Main objective

H2PlasmaRed Project

The main objective of H2PlasmaRed is to develop a green CO2-free steelmaking route based on H2-plasma technology while promoting a circular economy by valorizing industrial sidestreams to meet the targets of the European Green Deal for reducing CO2 emissions in the steel industry across Europe.

Our ambition is to introduce a near CO2 free reduction process to strive for the goal of Paris Agreement – a 90% reduction in the carbon intensity the steel production by 2050.

To achieve this H2PlasmaRed will:

- Explore the fundamentals of the hydrogen plasma smelting reduction (HPSR) process.

- Develop HPSR from TRL5 to TRL7 by demonstrating the HPSR in a pilot-HPSR reactor (hundred-kilogram-scale) and a pilot-scale DC electric arc furnace (5-ton scale) by retrofitting the existing furnace.

- evelop innovative solutions for process control and modeling, along with state-of-the-art technologies for retrofitting existing industrial furnaces and significantly increasing industrial viability.

- Establish a framework for upscaling and uptake of the processes by integrating life cycle and safety assessment, economic evaluation, and exploitation strategy in the technology development.

- Emphasize energy and resource efficiency, H2-safety, and fundamental understanding of HPSR,enabling long-lasting impact and deployment of the technology in Europe in the coming decades.

Work plan

Work Packages

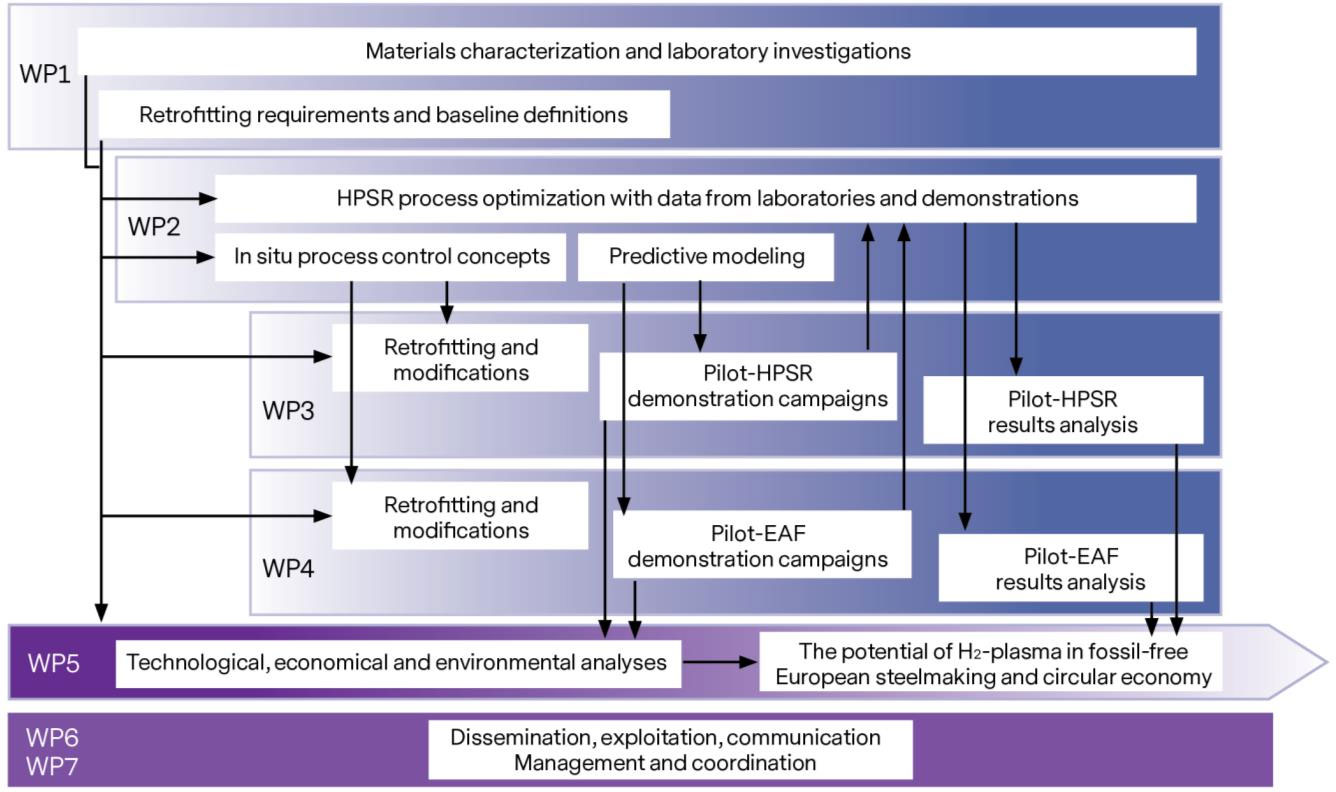

H2PlasmaRed project consists of 4 technical Work Packages and 3 non-technical Work Packages

- WP1: Process analysis, characterization, and baseline definitions

- WP2: Hydrogen plasma smelting reduction process optimization

- WP3: Demonstration at pilot-HPSR plant

- WP4: Demonstration at retrofitted pilot-EAF

- WP5: Technological, economic, and environmental impact

- WP6: Dissemination, exploitation, and communication

- WP7: Management and Coordination